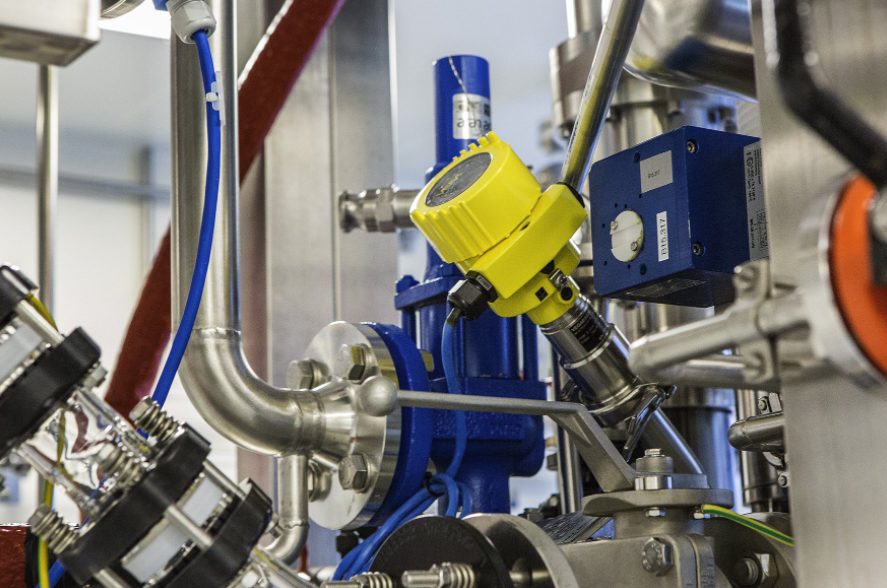

A differential pressure measurement is used to measure differential strain. It is a cutting edge instrument that shows the change between two data affiliations. It can without a very remarkable stretch measure any pressure change in liquids and gases.

It is most key when two system inputs have a basic differentiation in pressure. There are different kinds of strain checks open watching out. One can pick the actual take a look at that best suits their prerequisites.

The chief kind is the Piston Sensor Differential Pressure Gauge

This is the most outstanding and customarily used check. It is a sensible sort of strain assessing instrument that is used in assessing the level of contamination in a filtration system.

The action and the switch hinder the movement of the fluid in a filtration system from ending. Moreover, these two segments stifle the cartridge filtration structure from falling. This kind of differential pressure transmitter involves a sliding seal that is basically comparable to a hypodermic needle seal.

The seal allows nearly nothing and minuscule media in the system to move from the high strain to the low pressure areas. These include the highest level of pressure and the range of differential pressures that the sensor can take.

Another kind of check is the Rolling Diaphragm Differential Pressure Gauge

Here boundless or obscure proportions of media advancement are not allowed. This kind of measure is furthermore used for filtration purposes. Also, it is used in heat exchangers and other liquid structures that require positive strain to monitor it.

This sort of measure isn’t proposed for structures that get an opportunity of pressure return again. A third kind of Differential Pressure Gauge is the sort with a Small Convoluted Diaphragm.

This sort of check is proposed in assessing strain with low ranges since it can perceive lower pressure totals. In like manner, it has a greater area that can slow down pressure.

This sort of check is usually used in showing liquid level and opening, venturi or spout stream rate. The liquid level and stream rate pressures are assessed as a square base of the differential strain. The little tangled stomach check can get this assessment by using exceptional square root dials.

FINAL THOUGHTS

So in the conclusion we can say that a differential pressure measurement is the differentiation between two strain assessments inside two concentrations in a lone structure. This sort of assessment is regularly used in systems with instruments having pressure limits like environment, plane and auto structures.

For more information visit our Website.